Product Development

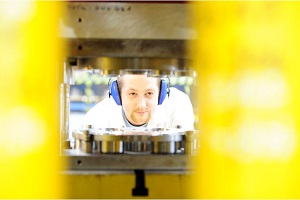

ArcelorMittal's product development approach is based on the long-term co-development agreements we have with our customers and on the daily technical support we provide. From ArcelorMittal's Global Research and Development Centres to European plants, our experts are committed to improving steel processing and engineering.

How?

- understanding operational drivers and product evolutions

- inventing products for tomorrow's applications

- fine-tuning processes

- improving product quality

- identifying cost reductions and performance improvements

What?

Our research and development teams provide support to our customers to establish a sound knowledge on the key expectations from our products such as

- cleanliness

- structural homogeneity

- mechanical characteristics

- corrosion resistance

- etc.

Beyond this, our research and development mission is to develop new steel solutions to address future segment needs. Some of them are already being used by our customers:

- bainitic grades for forging (Solam®)

- high plasticity and high strength grades for cold heading (FreeForm®)

- high machinability grades

We have developed models describing in detail the overall steel production process, from liquid metallurgy to hot rolling and cold forming connecting microstructural behaviour, thermomechanical process to steel product or part performance. Final thermal treatment simulations help our partners to reach very high process control and increase its robustness. Specific pilot plants for casting, rolling, drawing and heat treatment complement numerical simulations by providing material for physical evaluation.

Drawability and machinability are specific areas of research and product development with dedicated pilot benches, as well as specific and instrumented lathes, new ultrasonic tank to optimise cleanliness.

Our labs are equipped with the most recent technologies for macro/micro characterisation (field emission gun SEM, macro-probe, torsion & fatigue machines (new Charpy & Brugger impact test), dilato-plastometer, corrosion chambers…) and provide support through process instrumentation (thermal cameras, pyrometers, force sensors, etc.). Specific surface expertise can be provided for wire: surface morphology (new 3D non contact profiler), composition new H2 and aptitude to coating.

Our customers can rely on the expertise of ArcelorMittal's Global R&D Centres, as well as on our international network of experts available on every continent, to manage the world's largest steel product portfolios.