XCarb®

At the forefront of technical innovation provide best-in-class customer service

At the heart of Europe's industrial might, ArcelorMittal Europe stands as a beacon of innovation and excellence in the production of bars and wire rod. With a storied tradition across key locations such as Germany, France, and Poland, our plants are not just manufacturing hubs but crucibles of technical advancement.

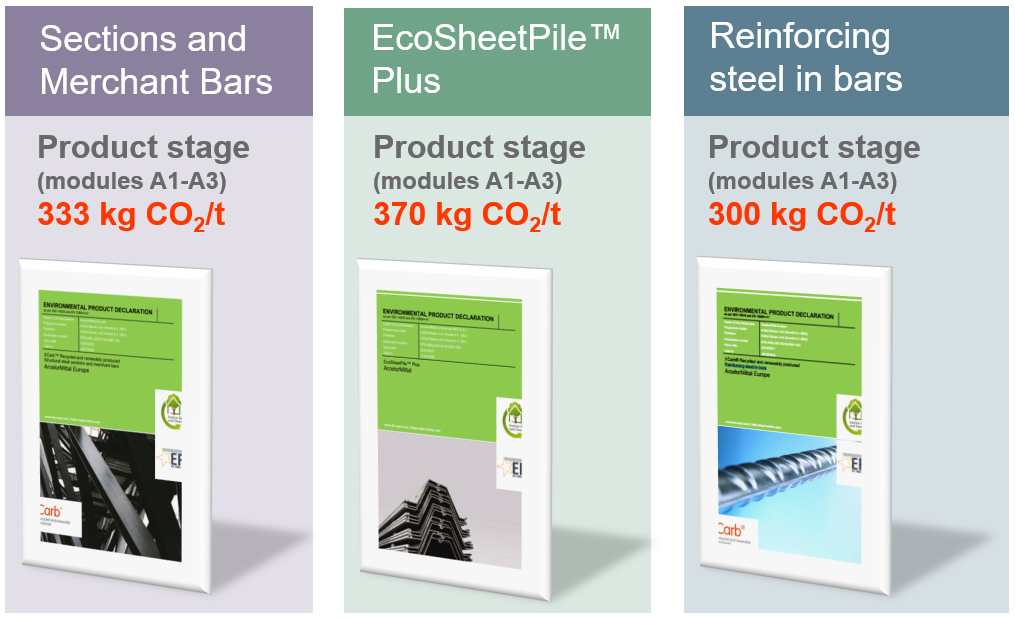

XCarb® is ArcelorMittal's towards net zero steel transformation programme. It brings together all of the company's reduced, low and zero-carbon steel products, processes, technologies, innovation projects, initiatives and alliances in one single-minded effort to make the changes needed to get our organisation and industry to net zero by 2050. It is fundamental to ArcelorMittal becoming the 'steel company of the future.'

One of the first decarbonisation initiatives from ArcelorMittal Europe – Long Products is XCarb® recycled and renewably produced. To produce XCarb® recycled and renewably produced steel, ArcelorMittal Europe – Long Products uses up to 100-percent scrap.

Read our Environmental Product Declaration to know more.

Construction & infrastructure

- Cold heading: Engineered for durable construction fasteners

- Drawing and cold rolling: Customized for structural flexibility and strength

- Prestressed concrete: Reinforced for enhanced load-bearing capacity

- Alloyed Spring: Designed for shock absorption in structural applications

- Rebar / mesh: Fundamental for reinforcing concrete structures

- Welding: Specialized for robust connections in construction projects

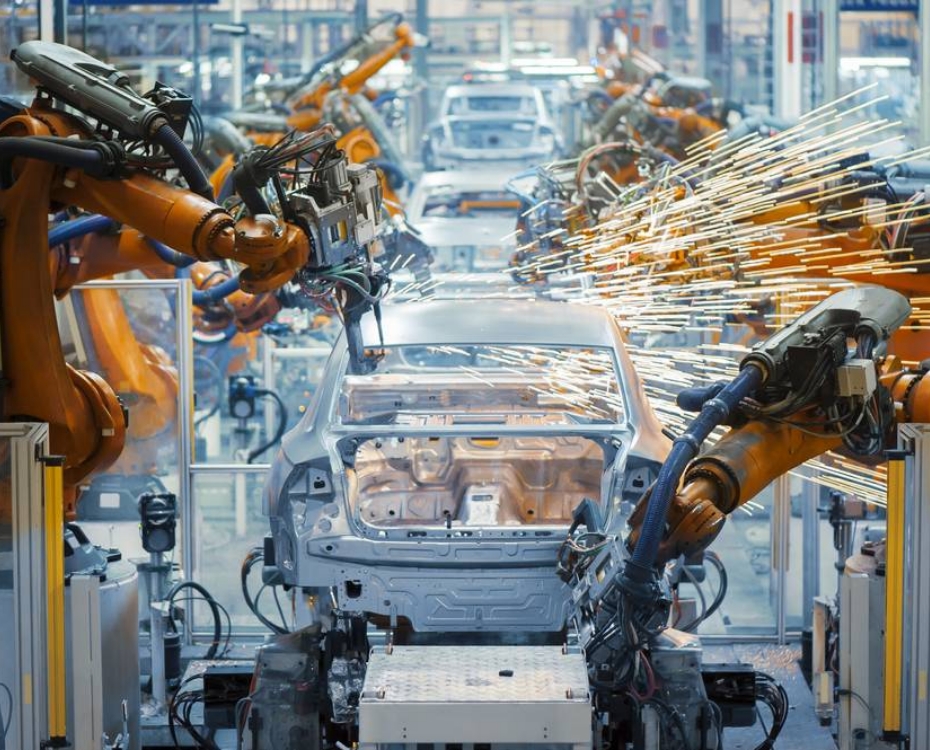

Automotive

- Bearing: Precision-crafted for smooth operation

- Chains: Robust links for reliable connectivity

- Cold heading: Molded for high-strength fasteners

- Drawing and cold rolling: Tailored for exceptional flexibility and strength

- Forging: Heat-treated for unmatched toughness

- Free cutting: Designed for easy machining efficiency

- Alloyed Spring: Optimized for superior elasticity

- Steel cord, hose wire, bead wire: Core components for structural integrity

- Welding: Formulated for seamless joints and repairs

Mechanical engineering

- Bearing: Crafted for frictionless movement and load support

- Chains: Strong links for mechanical reliability

- Cold heading: Shaped for high-performance components

- Drawing and cold rolling: Tailored for enhanced durability and precision

- Forging: Forged for superior strength in critical applications

- Free cutting: Optimized for effortless machining and assembly

- Alloyed Spring: Engineered for optimal flexibility and resilience

- Welding: Developed for secure and lasting mechanical joints

Energy

- Bearing: Precision-engineered for high-load energy applications

- Cold heading: Formed for enduring energy infrastructure fasteners

- Drawing and cold rolling: Customized for critical energy transmission components

- Forging: Forged for robustness in energy generation and distribution

- Free cutting: Designed for seamless integration into energy systems

- Hose wire: Reinforced for high-pressure energy transport applications

- Welding: Advanced solutions for strong and reliable energy constructions

Latest news

10 October 2025

10 October 2025

ArcelorMittal announces a new Chief Marketing Officer for Bars and Rods division in Europe

14 April 2025

14 April 2025

Thank you for visiting us at WindEurope 2025 in Copenhagen!

25 March 2025

25 March 2025

Join ArcelorMittal at WindEurope 2025 in Copenhagen

14 October 2024

14 October 2024

Our full WindEnergy video is now live

27 September 2024

27 September 2024

XCarb® recycled and renewably produced in the spotlight at WindEnergy in Hamburg

16 September 2024

16 September 2024

ArcelorMittal at WindEnergy Hamburg 2024: Smarter steels for people and planet

17 June 2024

17 June 2024

ArcelorMittal introduces latest developments at Wire and Tube fair

16 April 2024

16 April 2024

Museum of the History of Polish Jews reinforced with ArcelorMittal rebars

1 April 2024

1 April 2024

Get your shopping list ready for the 64,000 m² shopping centre in Warsaw

1 April 2024

1 April 2024

Krybar® in the Al-Zour LNG project in Kuwait

1 April 2024

1 April 2024

ArcelorMittal helps Warsaw grow

29 March 2024

29 March 2024

LISI AUTOMOTIVE and ArcelorMittal join forces to help transform the automotive industry with XCarb® recycled and renewably produced low carbon-emissions steel

22 March 2024

22 March 2024

The XCarb® Recycled and renewably produced EPD is now available for rebars

22 March 2024

22 March 2024

ArcelorMittal Hamburg delivers the first tonnes of XCarb® recycled and renewably produced wire rod to Waelzholz

22 March 2024

22 March 2024