Cold heading

Automotive , Construction & infrastructure , Energy , Mechanical engineering

Screws, bolts, rivets, etc. are produced by cold heading: a process of high productivity using punch and dies to transform a steel wire rod at room temperature. A specific quenching and tempering process regularly follows cold heading in order to reach the final mechanical properties.

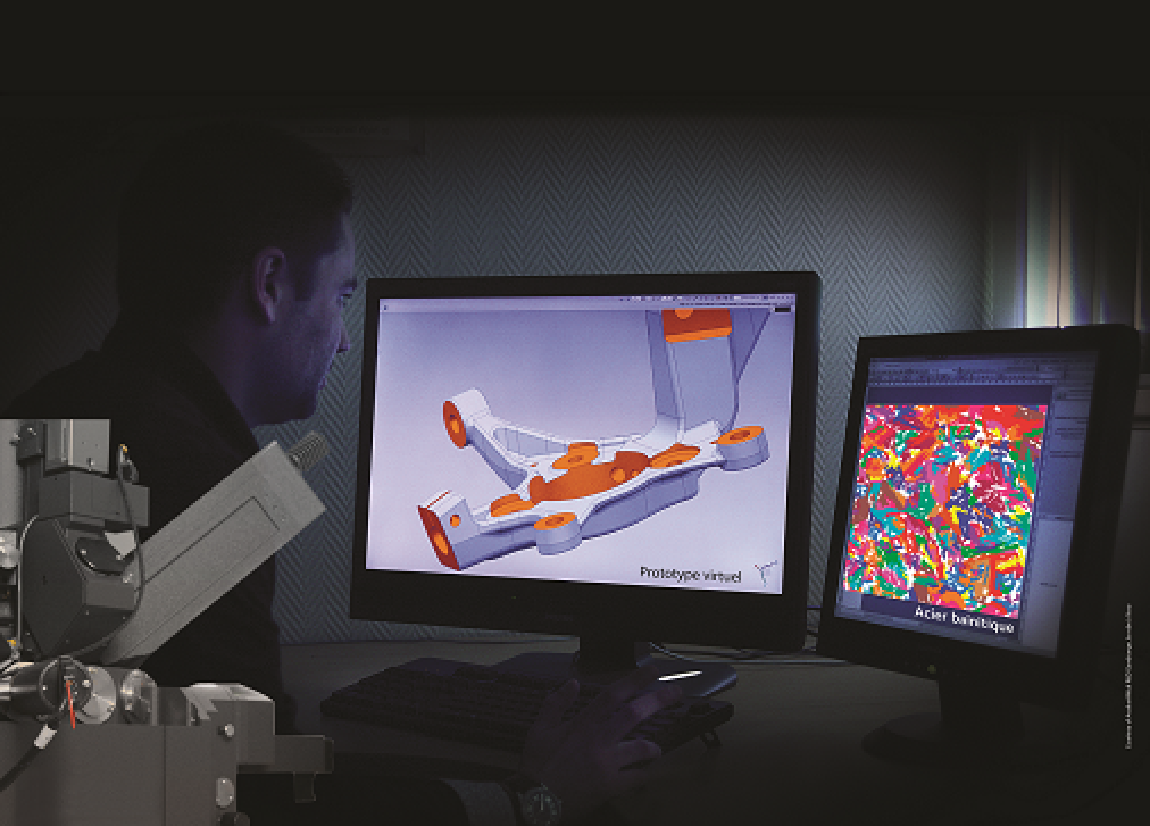

Ductility and strength required for cold heading are obtained by a wide range of low carbon, alloyed and boron grades produced according to international standards. Bainitic grades are also used in specific applications.

The steel grade is accordingly alloyed with elements such as manganese, chromium, boron and molybdenum depending on the final class targeted (8.8, 9.8, 10.9, 12.9). The chemical analysis is a trade-off between the necessary ductility prior to processing and the final properties obtained after quenching and tempering.

Specific grades have been developed for engine bolts with an ultimate tensile strength of over 1500 MPa and improved hydrogen resistance for a range from M6 to M14. The ultimate tensile strength of such grades can be adjusted in the range of 1200 - 1500 MPa with the adjustment of the tempering process to meet the requirements of 12.9 class bolts.

Key properties

Products used

20MnB5 screw: hardness profile, thermal simulation

| Class | C | Si | Mn | P | S | Cr | Ni | Mo | Al | V | B | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Material No. | 4.6 | 5.6 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 | % | % | % | % | % | % | % | % | % | % | ppm |

| C4C | 1.0303 | X | X | X | 0.02-0.06 | max. 0.10 | 0.25-0.40 | max. 0.02 | max. 0.025 | - | - | - | 0.02-0.06 | - | - | ||||

| C8C | 1.0213 | X | X | X | 0.06-0.10 | max. 0.10 | 0.25-0.45 | max. 0.02 | max. 0.025 | - | - | - | 0.02-0.06 | - | - | ||||

| C10C | 1.1214 | X | X | X | 0.08-0.12 | max. 0.10 | 0.30-0.50 | max. 0.025 | max. 0.025 | - | - | - | min. 0.02 | - | - | ||||

| C15C | 1.1234 | X | X | X | 0.13-0.17 | max. 0.10 | 0.35-0.60 | max. 0.025 | max. 0.025 | - | - | - | min. 0.02 | - | - | ||||

| C20C | 1.0411 | X | X | X | 0.18-0.22 | max. 0.10 | 0.70-0.50 | max. 0.025 | max. 0.025 | - | - | - | 0.02-0.06 | - | - | ||||

| C22 | 1.0402 | X | X | X | 0.20-0.24 | max. 0.15 | 0.40-0.60 | max. 0.015 | max. 0.015 | - | - | - | - | - | - | ||||

| 6MnB6 | X | 0.06-0.10 | 0.05-0.40 | 1.30-1.60 | max. 0.025 | max. 0.025 | max. 0.30 | - | - | - | - | 100-200 | |||||||

| 17MnB4 | 1.5520 | X | 0.15-0.20 | max. 0.30 | 0.90-1.20 | max. 0.025 | max. 0.025 | max. 0.30 | - | - | - | - | 8-50 | ||||||

| 20MnB4 | 1.5525 | X | X | X | 0.18-0.23 | max. 0.30 | 0.90-1.20 | max. 0.025 | max. 0.025 | max. 0.30 | - | - | - | - | 8-50 | ||||

| 23MnB4 | 1.5535 | X | X | X | 0.20-0.25 | max. 0.30 | 0.90-1.20 | max. 0.025 | max. 0.025 | max. 0.30 | - | - | - | - | 8-50 | ||||

| 28B2 | 1.5510 | X | X | X | 0.25-0.30 | max. 0.30 | 0.60-0.90 | max. 0.025 | max. 0.025 | max. 0.30 | - | - | - | - | 8-50 | ||||

| 30MnB4 | 1.5526 | X | X | X | 0.27-0.32 | max. 0.30 | 0.80-1.10 | max. 0.025 | max. 0.025 | max. 0.30 | - | - | - | - | 8-50 | ||||

| 32CrB4 | 1.7076 | X | 0.30-0.34 | max. 0.30 | 0.60-0.90 | max. 0.025 | max. 0.025 | 0.90-1.20 | - | - | - | - | 8-50 | ||||||

| 38B2 | 1.5515 | X | 0.35-0.40 | max. 0.30 | 0.60-0.90 | max. 0.025 | max. 0.025 | max. 0.30 | - | - | - | - | 8-50 | ||||||

| 36CrB4 | 1.7077 | X | 0.34-0.38 | max. 0.30 | 0.70-1.00 | max. 0.025 | max. 0.025 | 0.90-1.20 | - | - | - | - | 8-50 | ||||||

| 30CrMoB1 | X | 0.28-0.32 | max. 0.30 | 0.80-1.10 | max. 0.015 | max. 0.015 | 0.15-0.30 | - | 0.08-0.15 | 0.02-0.06 | - | 8-50 | |||||||

| 27MnSiVS6 | 1.5232 | 0.25-0.30 | 0.15-0.80 | 1.20-1.60 | 0.025 | 0.025 | - | - | - | - | 0.08-0.20 | - | |||||||

| 34CrMo4 | 1.7220 | X | 0.30-0.37 | max. 0.30 | 0.60-0.90 | max. 0.025 | max. 0.025 | 0.90-1.20 | - | 0.15-0.30 | - | - | - | ||||||

| 34CrNiMo6 | 1.6582 | X | 0.30-0.38 | max. 0.30 | 0.50-0.80 | max. 0.025 | max. 0.025 | 1.30-1.70 | 0.90-1.20 | 0.15-0.30 | - | - | - | ||||||

| 41CrS4 | 1.7039 | X | 0.38-0.45 | max. 0.30 | 0.60-0.90 | max. 0.025 | max. 0.025 | 0.90-1.20 | - | - | - | - | - | ||||||

ArcelorMittal at NEMU 2019

ArcelorMittal Europe – Long Products' Business Division Bars & Rods will participate to NEMU, the International Conference dedicated to bulk metal forming, taking place on 14 and 15 May in Stuttgart, Germany.