Free cutting

Automotive , Energy , Mechanical engineering

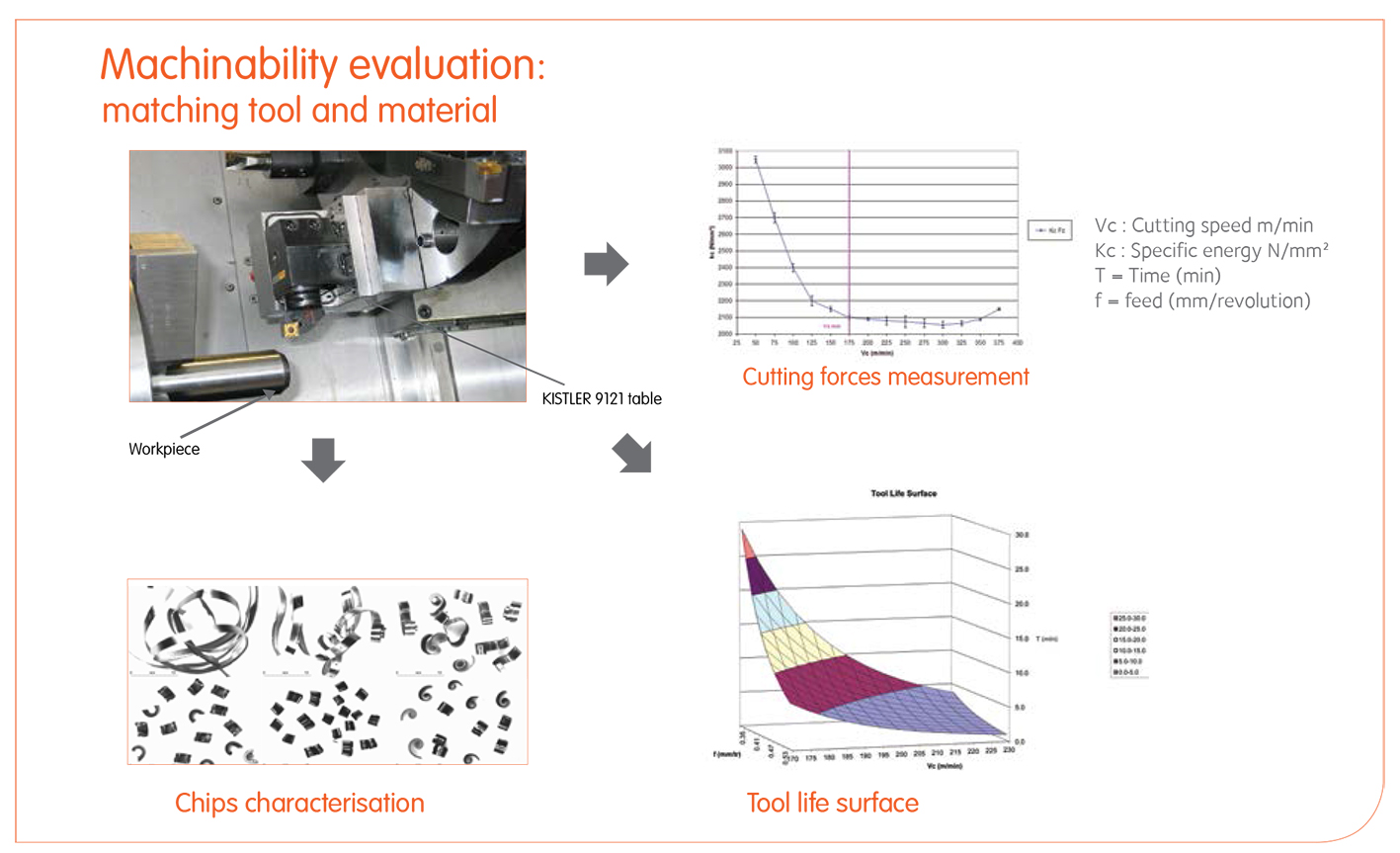

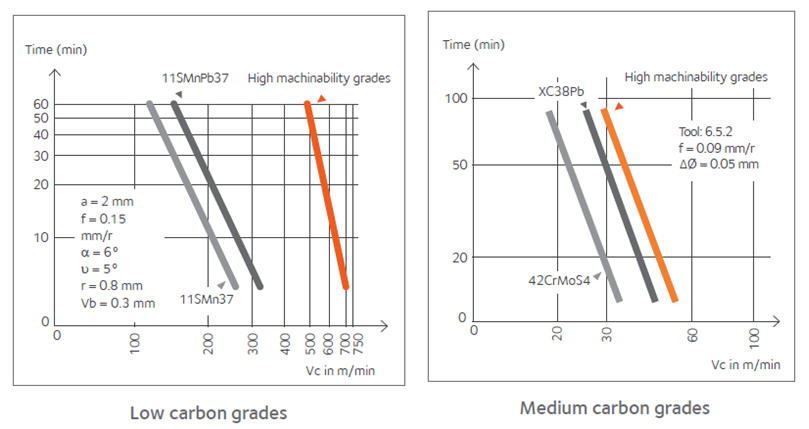

The metallurgy of free cutting steels is first determined by their expected machinability. The second parameters to take into account are the final mechanical properties required.

Very high mechanical properties can require alloying elements, heat treatment such as quenching and tempering, or surface treatment such as inductive hardening or case hardening.

Machining behaviour is obtained through specific alloying. Historically, lead (Pb) was the element used to improve machinability for its lubricating effect. Nowadays, lead-free grades have been developed using calcium, tellurium, bismuth, selenium, etc. Sulphur influences inclusion morphology and improves tool life.

Special steel grades have been developed for improved fatigue requirements while keeping high machinability levels.

Key properties

Products used

| C | Si | Mn | P | S | Pb | ||

|---|---|---|---|---|---|---|---|

| Name | Material No. | % | % | % | % | % | % |

| 11SMn30 | 1.0715 | max. 0.14 | max. 0.05 | 0.90-1.30 | max. 0.11 | 0.27-0.33 | - |

| 11SMnPb30 | 1.0718 | max. 0.14 | max. 0.05 | 0.90-1.30 | max. 0.11 | 0.27-0.33 | 0.20-0.35 |

| 11SMn37 | 1.0736 | max. 0.14 | max. 0.05 | 1.00-1.50 | max. 0.11 | 0.34-0.40 | - |

| 11SMnPb37 | 1.0737 | max. 0.14 | max. 0.05 | 1.00-1.50 | max. 0.11 | 0.34-0.40 | 0.20-0.35 |

| SAE1215 | 1.9704 | max. 0.05 | - | 0.75-1.05 | 0.04-0.05 | 0.26-0.35 | - |

| SAE1214 | 1.0718 | max. 0.15 | - | 0.85-1.15 | 0.04-0.05 | 0.26-0.35 | 0.15-0.35 |

| C10Pb | - | 0.06-0.12 | max. 0.04 | 0.25-0.50 | max. 0.045 | max. 0.045 | 0.15-0.30 |

| 10S20 | 1.0721 | 0.07-0.13 | max. 0.04 | 0.70-1.10 | max. 0.06 | 0.15-0.25 | - |

| 10S20Pb | 1.0722 | 0.07-0.13 | max. 0.04 | 0.70-1.10 | max. 0.06 | 0.15-0.25 | 0.20-0.35 |

| 35S20 | 1.0726 | 0.32-0.39 | max. 0.04 | 0.70-1.10 | max. 0.06 | 0.15-0.25 | - |

| 35Sppb20 | 1.0756 | 0.32-0.39 | max. 0.04 | 0.70-1.10 | max. 0.06 | 0.15-0.25 | 0.15-0.25 |

| 36SMn14 | 1.0764 | 0.32-0.39 | max. 0.04 | 1.30-1.70 | max. 0.06 | 0.10-0.18 | - |

| 36SMnPb14 | 1.0765 | 0.32-0.39 | max. 0.04 | 1.30-1.70 | max. 0.06 | 0.10-0.18 | 0.15-0.25 |

| 38SMn28 | 1.0760 | 0.35-0.40 | max. 0.04 | 1.20-1.50 | max. 0.06 | 0.24-0.33 | - |

| 38SMnPb28 | 1.0761 | 0.35-0.40 | max. 0.04 | 1.20-1.50 | max. 0.06 | 0.24-0.33 | 0.15-0.35 |

| 44SMn28 | 1.0762 | 0.40-0.48 | max. 0.04 | 1.30-1.70 | max. 0.06 | 0.24-0.33 | - |

| 44SMnPb28 | 1.0763 | 0.40-0.48 | max. 0.04 | 1.30-1.70 | max. 0.06 | 0.24-0.33 | 0.15-0.35 |

| 46S20 | 1.0727 | 0.42-0.50 | max. 0.04 | 0.70-1.10 | max. 0.06 | 0.15-0.25 | - |

| 46SPb20 | 1.0757 | 0.42-0.50 | max. 0.04 | 0.70-1.10 | max. 0.06 | 0.15-0.25 | 0.15-0.35 |

| C45Pb | - | 0.42-0.50 | max. 0.40 | 0.50-0.80 | max. 0.045 | max. 0.045 | 0.15-0.30 |

| 16MnCrS5Pb | - | 0.14-0.19 | max. 0.40 | 1.00-1.30 | max. 0.025 | max. 0.035 | 0.20-0.35 |