XCarb® recycled and renewably produced in the spotlight at WindEnergy in Hamburg

Six ArcelorMittal entities joined forces this week, bringing together our colleagues from multiple countries to attend WindEnergy Hamburg, which concludes on September 27th.

Together, we showcased our commitment to a low-carbon future in wind energy with XCarb® recycled and renewably produced, our low-carbon emissions steel range, which is helping to transform the wind energy industry by significantly reducing the carbon footprint of steel used in the wind sector.

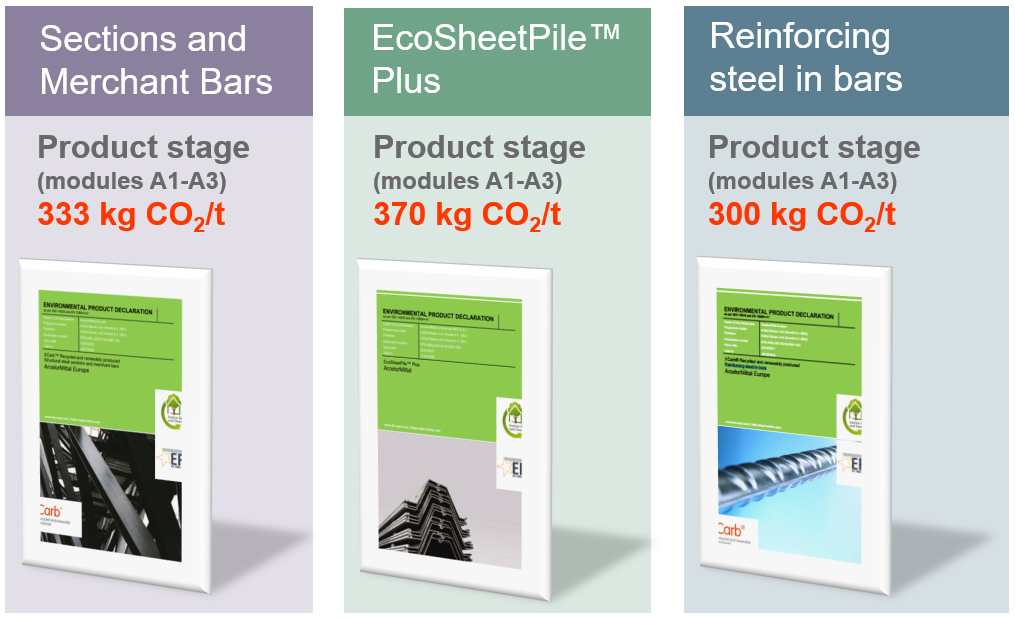

Steel plays a vital role in the energy transition, and as the leading material in the construction of wind turbines, it’s essential that this steel is produced sustainably. ArcelorMittal’s XCarb® recycled and renewably produced products deliver substantial CO₂ reductions, offering the only low-carbon emissions steel with certified Environmental Product Declarations (EPD) in Europe. This innovation has already been deployed in prestigious wind energy projects, supporting Europe’s shift to renewable energy.

With extensive experience in the wind energy sector, ArcelorMittal has supplied steel for more than 10,000 wind turbine towers, offshore substations, foundations, and cutting-edge floating wind developments. As one of Europe’s leading steel producers, we offer comprehensive, customised steel solutions for both onshore and offshore projects, including wind turbine foundations, jackets, and topsides. Our expertise and experience make us a trusted partner for the most ambitious wind energy projects across Europe.

A European energy transition requires steel made in Europe, and ArcelorMittal is proud to support this important shift with our XCarb® recycled and renewably products range. Whether it’s our heavy plates, beams, wire products, or structural components, ArcelorMittal products are designed to meet the unique demands of the wind energy sector, with many available in low-carbon emissions XCarb® recycled and renewably products versions.

Latest news

10 October 2025

10 October 2025

ArcelorMittal announces a new Chief Marketing Officer for Bars and Rods division in Europe

14 April 2025

14 April 2025

Thank you for visiting us at WindEurope 2025 in Copenhagen!

25 March 2025

25 March 2025

Join ArcelorMittal at WindEurope 2025 in Copenhagen

14 October 2024

14 October 2024

Our full WindEnergy video is now live

27 September 2024

27 September 2024

XCarb® recycled and renewably produced in the spotlight at WindEnergy in Hamburg

16 September 2024

16 September 2024

ArcelorMittal at WindEnergy Hamburg 2024: Smarter steels for people and planet

17 June 2024

17 June 2024

ArcelorMittal introduces latest developments at Wire and Tube fair

16 April 2024

16 April 2024

Museum of the History of Polish Jews reinforced with ArcelorMittal rebars

1 April 2024

1 April 2024

Get your shopping list ready for the 64,000 m² shopping centre in Warsaw

1 April 2024

1 April 2024

Krybar® in the Al-Zour LNG project in Kuwait

1 April 2024

1 April 2024

ArcelorMittal helps Warsaw grow

29 March 2024

29 March 2024

LISI AUTOMOTIVE and ArcelorMittal join forces to help transform the automotive industry with XCarb® recycled and renewably produced low carbon-emissions steel

22 March 2024

22 March 2024

The XCarb® Recycled and renewably produced EPD is now available for rebars

22 March 2024

22 March 2024

ArcelorMittal Hamburg delivers the first tonnes of XCarb® recycled and renewably produced wire rod to Waelzholz

22 March 2024

22 March 2024