Steel cord, hose wire, bead wire

Steel for rubber reinforcement is a 5.5 mm hot rolled wire rod designed to be drawn down to 0.2 mm or less while reaching final mechanical properties over 4000 MPa.

For the steel producer it is the most demanding high carbon product. We have developed 0.9% carbon chromium alloyed grades to obtain high mechanical properties for thinner drawing to lighten tires and improve fuel efficiency. To achieve small drawn diameters and to avoid the risk of segregation and decarburisation, steel cleanliness is tightly controlled and inclusions are strictly monitored in terms of chemistry, density and size. Surface quality is the final success factor for achieving very fine drawing quality, enabling surface treatments such as brass plating to be applied.

Key properties

Products used

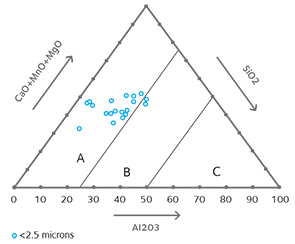

Typical inclusion distribution analysis by ternary diagram on steel cord

| C | Si | Mn | P | S | Cr | |

|---|---|---|---|---|---|---|

| Name | % | % | % | % | % | % |

| C60 | 0.55-0.65 | 0.15-0.30 | 0.40-0.80 | max. 0.03 | max. 0.03 | - |

| C70 | 0.65-0.75 | 0.15-0.30 | 0.40-0.80 | max. 0.03 | max. 0.03 | - |

| C80 | 0.75-0.88 | 0.15-0.30 | 0.40-0.80 | max. 0.03 | max. 0.03 | - |

| C90+Cr | 0.90-0.95 | 0.15-0.30 | 0.10-0.40 | max. 0.03 | max. 0.03 | 0.10-0.30 |