Welding

Automotive , Construction & infrastructure , Energy , Mechanical engineering

Steel welding grades are developed to guarantee coherent chemical and mechanical properties between the welded joint and the base metal.

The grade analysis is a determining factor, especially

- in obtaining the required mechanical properties: carbon, manganese and alloying elements such as vanadium or niobium;

- for toughness or corrosion resistance: nickel, chromium or molybdenum;

- depending on the welding process and on protection used (shielding gas or flux): carbon, silicon, aluminium or titanium to limit the risk of welded joint oxidation;

- residual content such as copper, chromium and tin are tightly controlled to avoid cracks, as are phosphorus, sulphur and hydrogen;

- special processes have been developed to achieve

a. ultra-low levels of residuals such as lead, bismuth

b. alloyed grades with up to 9% chromium, nickel, molybdenum…

All these metallurgical considerations explain the diversity of grades available for welding and which can only be partially covered by international standards.

Key properties

Grade analysis

Mechanical properties prior drawing by controlled cooling

Products used

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| % | % | % | % | % | % | % | % | % | |||

| Name | Standard | Applications | - | - | - | max. | max. | max. | max. | max. | max. |

| SG1 | ISO 14341 | Shielded arc welding | 0.06-0.10 | 0.50-0.70 | 1.00-1.30 | 0.015 | 0.015 | 0.10 | 0.10 | 0.05 | 0.10 |

| SG2 | ISO 14341 | Shielded arc welding | 0.06-0.09 | 0.80-0.90 | 1.40-1.50 | 0.015 | 0.015 | 0.10 | 0.10 | 0.05 | 0.10 |

| SG3 | ISO 14341 | Shielded arc welding | 0.06-0.09 | 0.85-1.00 | 1.60-1.70 | 0.015 | 0.015 | 0.10 | 0.10 | 0.05 | 0.10 |

| S1 | ISO 14171 | Stick electrode | 0.05-0.15 | max. 0.15 | 0.35-0.60 | max. 0.025 | max. 0.025 | max. 0.10 | max. 0.10 | max. 0.05 | max. 0.10 |

| S2 | ISO 14171 | Submerged arc welding | 0.07-0.15 | max. 0.15 | 0.80-1.30 | 0.025 | 0.025 | 0.10 | 0.10 | 0.05 | 0.10 |

| S3Si | ISO 14171 | Submerged arc welding | 0.07-0.15 | 0.15-0.40 | 1.20-1.85 | 0.025 | 0.025 | 0.10 | 0.10 | 0.05 | 0.10 |

| S2Mo | ISO 14171 | Submerged arc welding | 0.07-0.15 | 0.05-0.25 | 0.95-1.20 | 0.025 | 0.025 | 0.10 | 0.10 | 0.45-0.65 | 0.10 |

| S3Mo | ISO 14171 | Submerged arc welding | 0.07-0.15 | 0.05-0.25 | 1.20-1.75 | 0.025 | 0.025 | 0.10 | 0.10 | 0.45-0.65 | 0.10 |

| C | Si | Mn | Cu | Cr | Ni | V | Mo | Nb | N | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| % | % | % | % | % | % | % | % | % | % | ||

| Name | Standard | typ | typ | typ | typ | max. | max. | typ | max. | max. | typ |

| CrMo5 | ISO 24598 | 0.12 | 0.25 | 0.90 | - | 6.00 | - | - | 0.65 | - | - |

| Mn4Ni2CrMo | ISO 16834 | 0.12 | 0.80 | 1.80 | - | 0.50 | 2.50 | - | 0.50 | - | - |

| G2Ni2 | ISO 14341 | 0.08 | 0.80 | 1.40 | - | - | 2.70 | - | - | - | - |

| CrMo25i | ISO 21952 | 0.07 | 0.50 | 1.00 | - | 2.50 | - | - | 1.00 | - | - |

| SUNCC3 | ISO 14171 | 0.10 | 0.30 | 1.00 | 0.50 | 0.50 | 0.750 | - | - | - | - |

| 2C1MW | ISO 24598 | 0.120 | 0.120 | 0.80 | - | 2.60 | - | 0.30 | 1.00 | 0.022 | - |

| CrMo91 | ISO 24598 | 0.120 | 0.60 | 1.00 | - | 9.00 | 0.500 | 0.20 | 1.00 | 0.065 | 0.045 |

ArcelorMittal helps Warsaw grow

To contribute to the expansion of Warsaw underground, ArcelorMittal Europe – Long Products supplied more than 20,000 tonnes of rebars.

Latest news

10 octobre 2025

Find out more

ArcelorMittal announces a new Chief Marketing Officer for Bars and Rods division in Europe

14 avril 2025

Thank you for visiting us at WindEurope 2025 in Copenhagen!

We are incredibly grateful to everyone who visited our stand at WindEurope 2025 in Copenhagen. Your ...

Find out more

25 mars 2025

Join ArcelorMittal at WindEurope 2025 in Copenhagen

Join ArcelorMittal at WindEurope 2025 in CopenhagenWe are thrilled to invite you to WindEurope 2025,...

Find out more

14 octobre 2024

Our full WindEnergy video is now live

Our full WindEnergy video is now live 🙌 ! Hear from our team and see their presence at the event. Wa...

Find out more

27 septembre 2024

XCarb® recycled and renewably produced in the spotlight at WindEnergy in Hamburg

Six ArcelorMittal entities joined forces this week, bringing together our colleagues from multiple c...

Find out more

16 septembre 2024

ArcelorMittal at WindEnergy Hamburg 2024: Smarter steels for people and planet

ArcelorMittal is excited to announce our participation at WindEnergy Hamburg 2024, taking place from...

Find out more

17 juin 2024

ArcelorMittal introduces latest developments at Wire and Tube fair

Low carbon-emissions steel on the way: XCarb® recycled and renewably produced steel, made with a hig...

Find out more

16 avril 2024

Museum of the History of Polish Jews reinforced with ArcelorMittal rebars

Located in the former heart of Jewish Warsaw, the new Museum of the History of Polish Jews is a mode...

Find out more

1 avril 2024

Get your shopping list ready for the 64,000 m² shopping centre in Warsaw

Galeria Północna, a modern and functional new shopping centre has opened its doors in Warsaw (Poland...

Find out more

1 avril 2024

Krybar® in the Al-Zour LNG project in Kuwait

As from 2020, Kuwait will have a new liquefied natural gas (LNG) terminal, located near Kuwait City ...

Find out more

1 avril 2024

ArcelorMittal helps Warsaw grow

To contribute to the expansion of Warsaw underground, ArcelorMittal Europe – Long Products supplied ...

Find out more

29 mars 2024

LISI AUTOMOTIVE and ArcelorMittal join forces to help transform the automotive industry with XCarb® recycled and renewably produced low carbon-emissions steel

Committing to achieve carbon neutrality by 2050 and reducing CO2 emissions by 35% by 2030 in Europe,...

Find out more

22 mars 2024

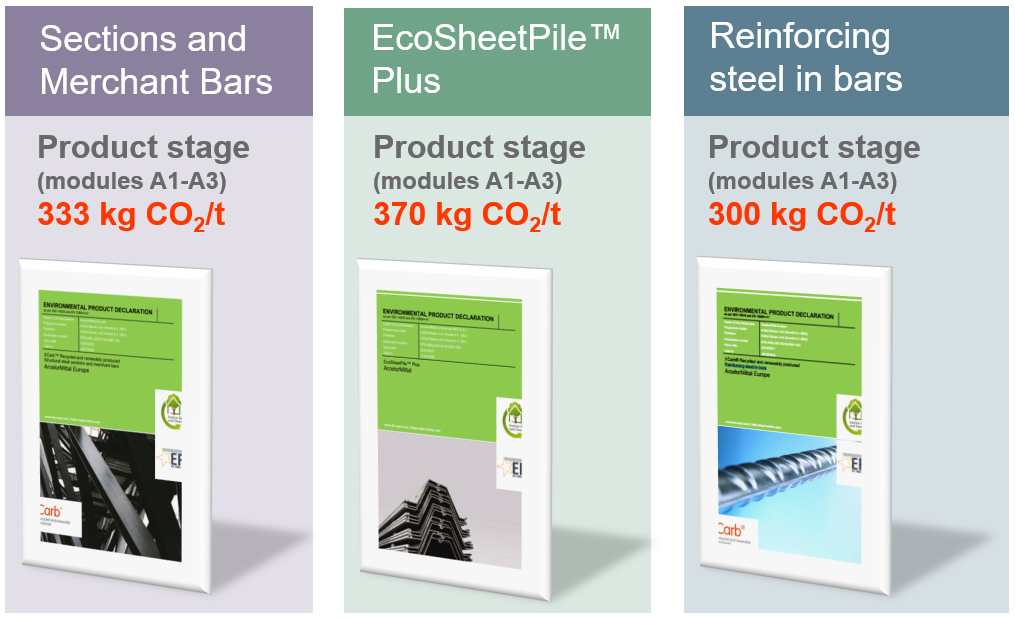

The XCarb® Recycled and renewably produced EPD is now available for rebars

After the announcement in July of the two first Environmental Production Declarations (EPDs) for its...

Find out more

22 mars 2024

ArcelorMittal Hamburg delivers the first tonnes of XCarb® recycled and renewably produced wire rod to Waelzholz

As part of their business partnership, ArcelorMittal will supply Waelzholz with XCarb® recycled and ...

Find out more

22 mars 2024

ArcelorMittal at Wire 2022

Committing to achieve carbon neutrality by 2050 and reducing CO2 emissions by 35%

Find out more

Other automotive applications

Steel cord, hose wire, bead wire

Steel for rubber reinforcement is a 5.5 mm hot rolled wire rod designed to be drawn down to 0.2 mm o...

Read More

Welding

Steel welding grades are developed to guarantee coherent chemical and mechanical properties between ...

Read More

Chains

Chains are produced by hot or cold forming and further quenching and tempering.Precise alloying is r...

Read More