Drawing and Cold rolling

Automotive , Construction & infrastructure , Energy , Mechanical engineering

Carbon steel grades for wire rod are classified in three families: low, medium and high carbon. The European standard EN 16120 for carbon grades defines a large range of grades with a carbon content from 0.03% to 1%.

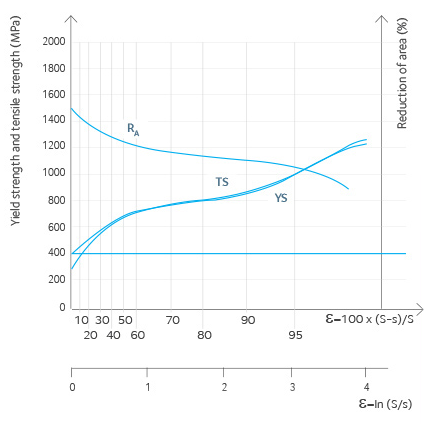

Carbon content is the first parameter for obtaining the final mechanical properties defined by international standards (EN, ASTM, JIS,…). For a wider range of properties, alloying elements such as boron, titanium, vanadium or chromium can be added.

The second parameter is strain hardening, induced by the drawing or rolling process. Specific customers’ requirements influence steel production standards to meet expected surface quality and ability for descaling or ultimate coating.

Key properties

Products used

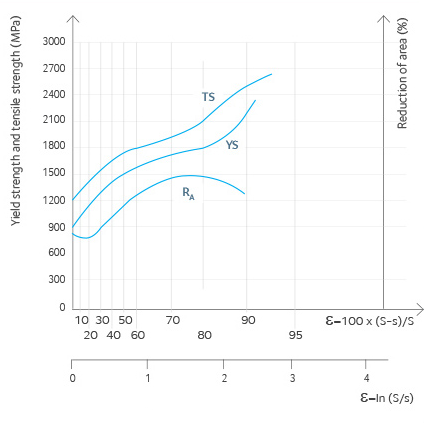

Evolution of tensile properties (yield strength, tensile strength, reduction of area) with strain hardening for low and high carbon grades

| C | Si | Mn | P | S | Cr | Ni | Cu | Al | TS* | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Material No. | % | % | % | % | % | % | % | % | % | MPa |

| - | - | - | max. | max. | max. | max. | max. | max. | - | ||

| C2D1 | 1.1185 | max. 0.03 | max. 0.05 | 0.10-0.35 | 0.02 | 0.02 | 0.10 | 0.10 | 0.10 | 0.01 | 330 |

| C3D1 | 1.1187 | max. 0.05 | max. 0.05 | 0.20-0.40 | 0.025 | 0.025 | 0.10 | 0.10 | 0.10 | 0.05 | 350 |

| C3D1 | 1.1187 | max. 0.05 | max. 0.05 | 0.20-0.40 | 0.025 | 0.025 | 0.10 | 0.10 | 0.10 | 0.05 | 350 |

| C3D1 | 1.1187 | max. 0.05 | max. 0.05 | 0.20-0.40 | 0.025 | 0.025 | 0.10 | 0.10 | 0.10 | 0.05 | 350 |

| C3D1 | 1.1187 | max. 0.05 | max. 0.05 | 0.20-0.40 | 0.025 | 0.025 | 0.10 | 0.10 | 0.10 | 0.05 | 350 |

| C3D1 | 1.1187 | max. 0.05 | max. 0.05 | 0.20-0.40 | 0.025 | 0.025 | 0.10 | 0.10 | 0.10 | 0.05 | 350 |

| C3D1 | 1.1187 | max. 0.05 | max. 0.05 | 0.20-0.40 | 0.025 | 0.025 | 0.10 | 0.10 | 0.10 | 0.05 | 350 |

| C3D1 | 1.1187 | max. 0.05 | max. 0.05 | 0.20-0.40 | 0.025 | 0.025 | 0.10 | 0.10 | 0.10 | 0.05 | 350 |

| C3D1 | 1.1187 | max. 0.05 | max. 0.05 | 0.20-0.40 | 0.025 | 0.025 | 0.10 | 0.10 | 0.10 | 0.05 | 350 |

| C3D1 | 1.1187 | max. 0.05 | max. 0.05 | 0.20-0.40 | 0.025 | 0.025 | 0.10 | 0.10 | 0.10 | 0.05 | 350 |

| C3D1 | 1.1187 | max. 0.05 | max. 0.05 | 0.20-0.40 | 0.025 | 0.025 | 0.10 | 0.10 | 0.10 | 0.05 | 350 |

Production sites for drawing and cold rolling applications

- Gandrange

Located in the Lorraine region in north-east France - Gijon

Located in the Asturias region in north-west Spain

Drawing and cold rolling

| Carbon | Low | Medium | High |

|---|---|---|---|

| Duisburg |

|

|

|

| Gandrange |

|

|

|

| Hamburg |

|

|

|

| Sonasid |

| ||

| Sosnowiec |

|

|

|

| Warszawa |

|

| |

| Zenica |

|

|

|