Longlife technology

Properties

Livespan

The wire lifespan is determined by the lifetime of the coating layer that protects the wire.

Corrosion

- The coating is subject to damages depending on the corrosive potential of the air and on the aggressiveness of the chemicals used for treatments.

- Pioneer in the heavily galvanized wires manufacturing, WireSolutions has invested steadily in the research of new coatings. Today, WireSolutions is well-known worldwide for the quality of its Crapal® coated wires.

Crapal®

Advantages

- Durable smooth surface

- Increased lifespan

- Concentricity: the required protection is only guaranteed if the protective layer is constant all around the wire.

- Less zinc oxides in the soil.

- CO2 footprint over time.

Livespan

Lifespan two times longer than EN 10244-2 heavily galvanised.

Lifespan four times longer than EN 10244-2 heavily galvanised.

Lifespan five times longer than EN 10244-2 heavily galvanised.

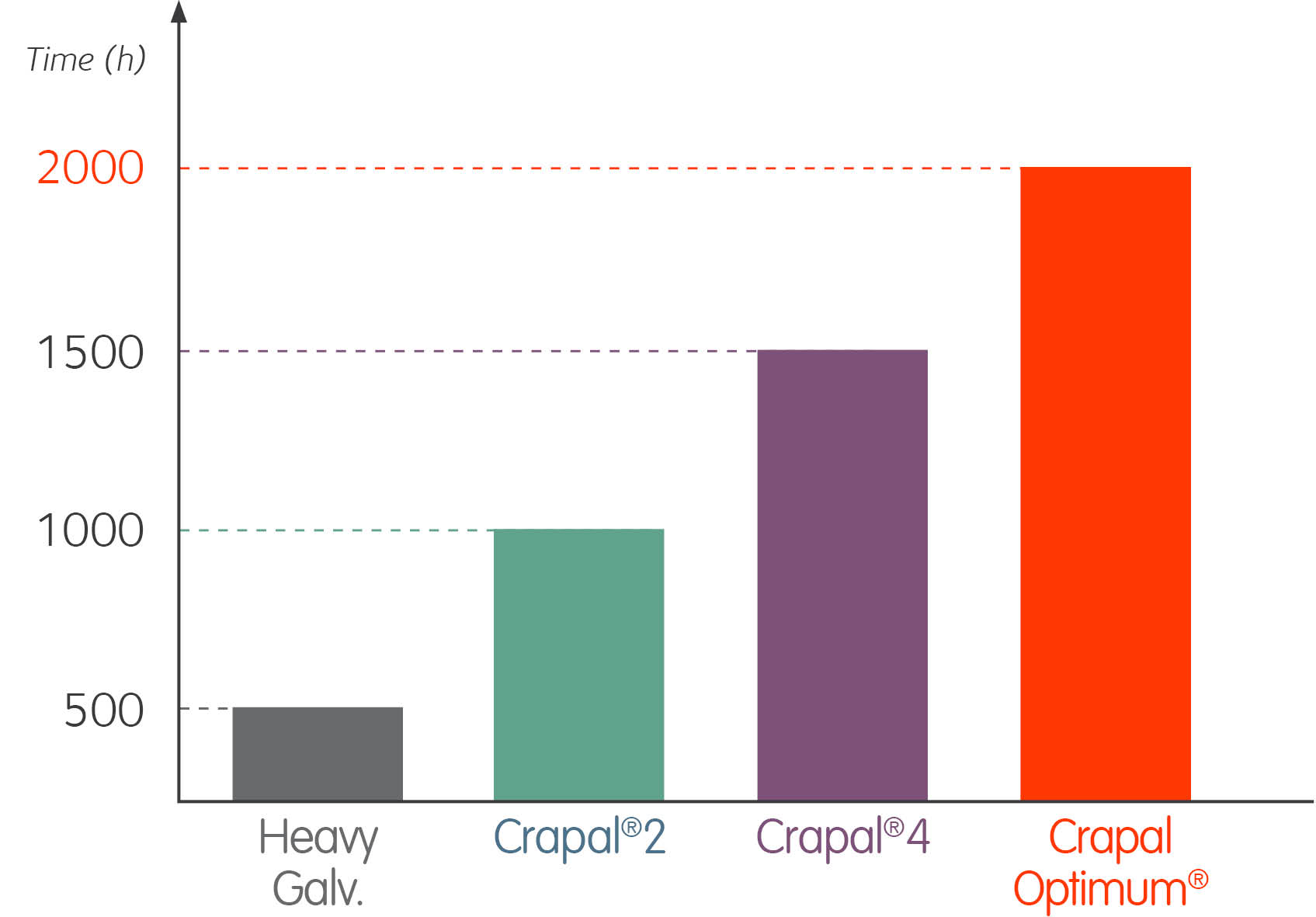

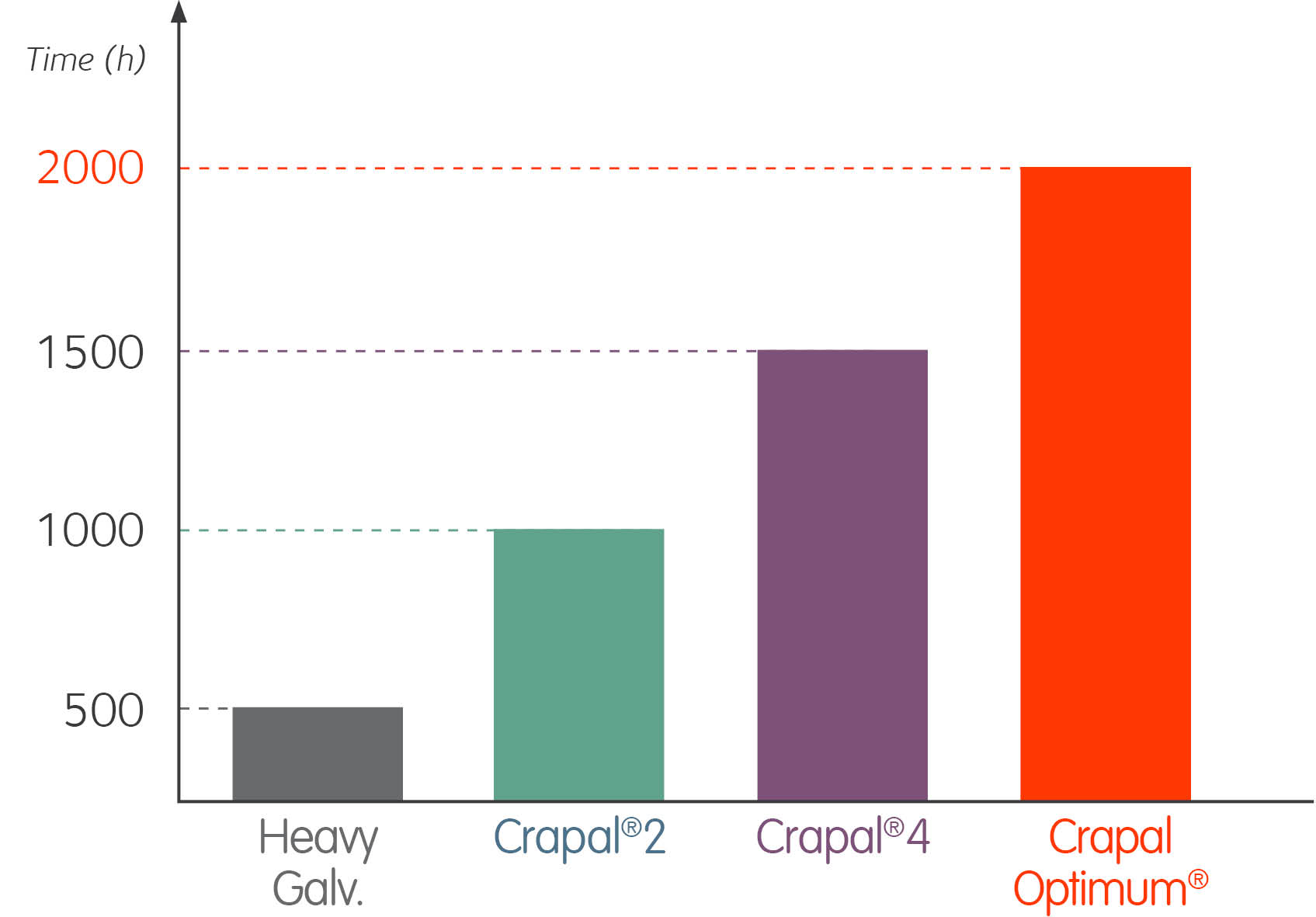

Salt spray test resistance

![]()

![]()

![]()