How is produced our Crapal® wire?

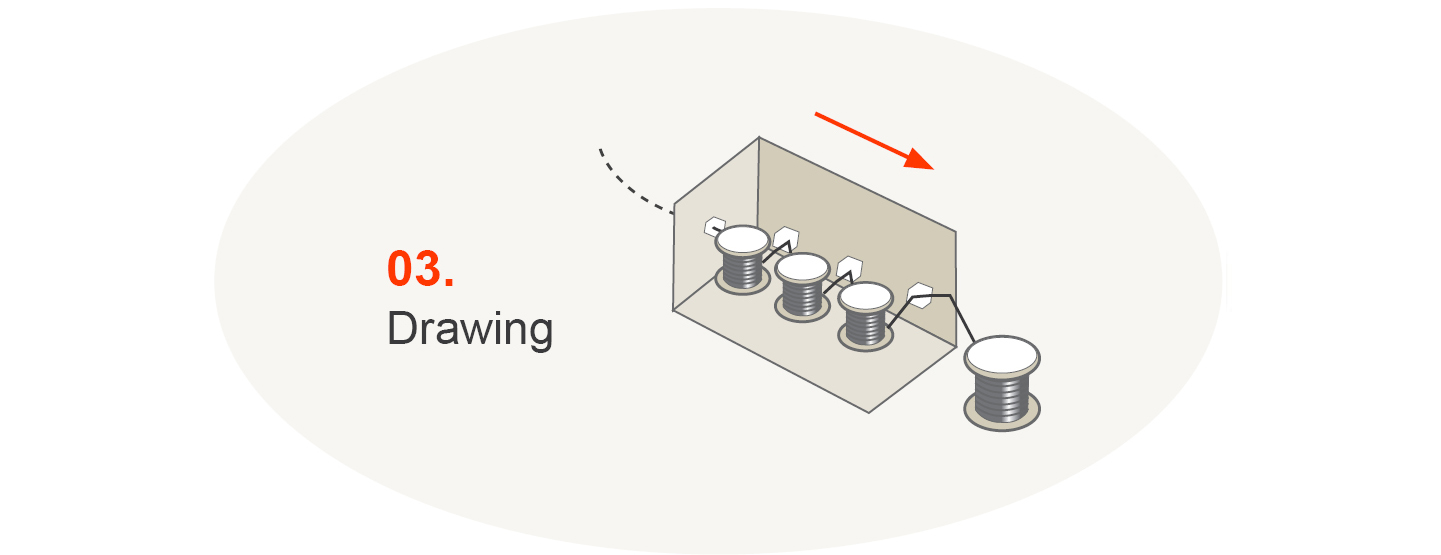

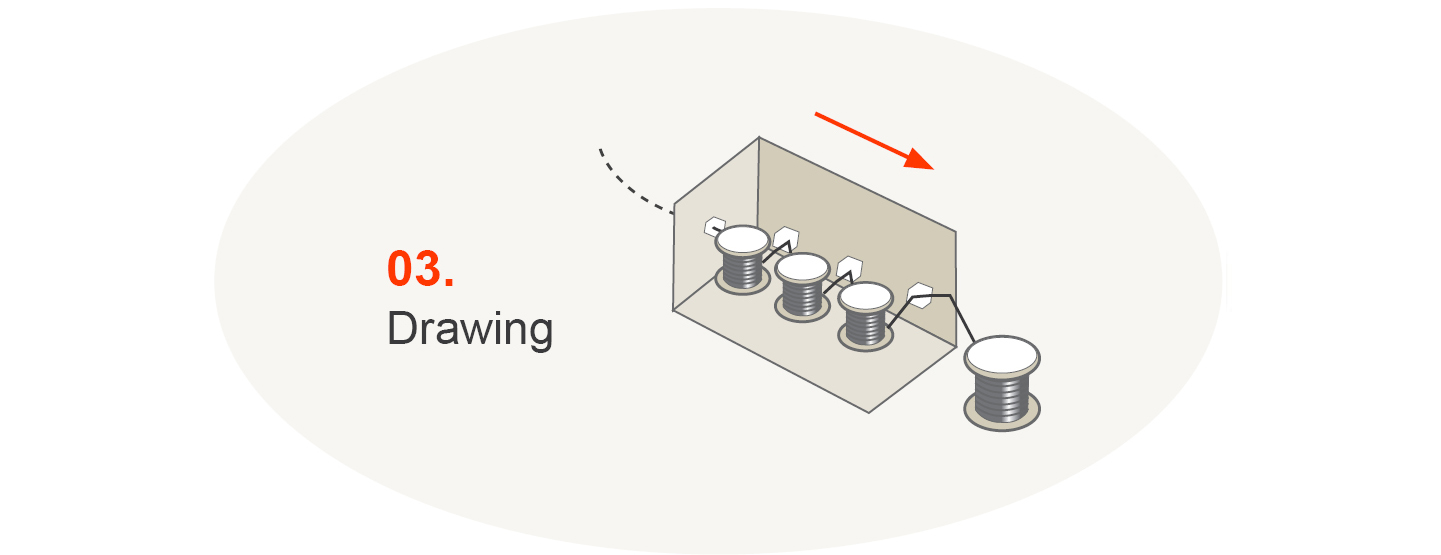

What is drawing?

- Reduction of the diameter step by step to reach the final characteristics.

- Strict respect of specifications is the key to meet the characteristics of the final product: regularity of shape and diameter to avoid deviation in breaking load and tensile strength.

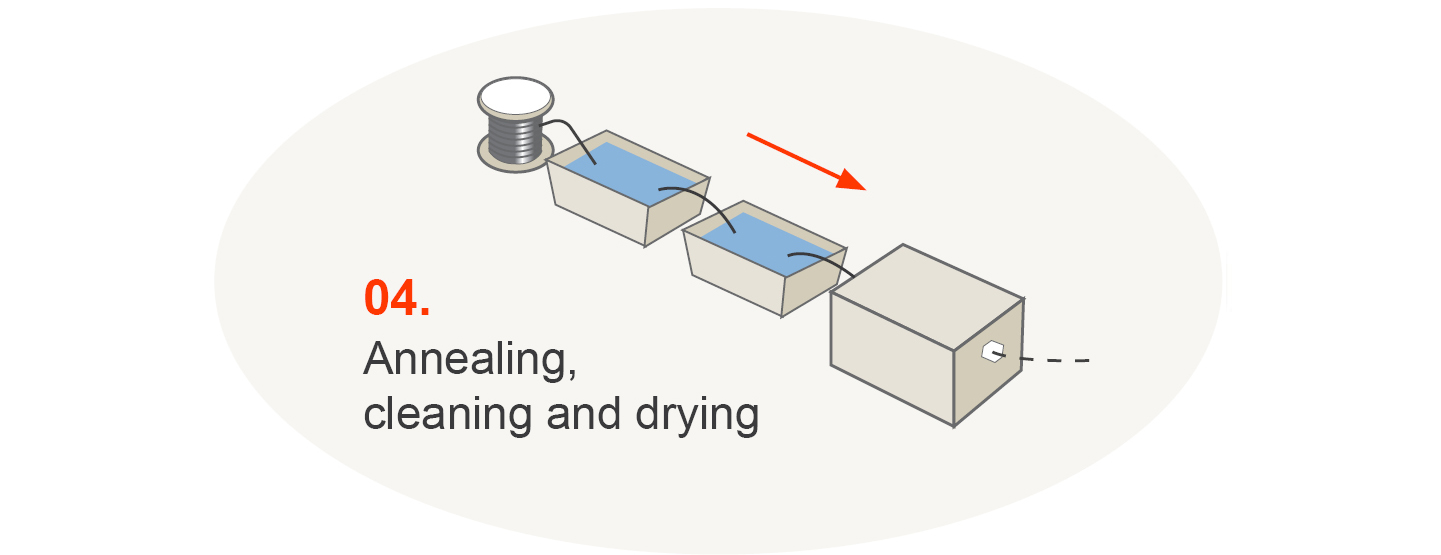

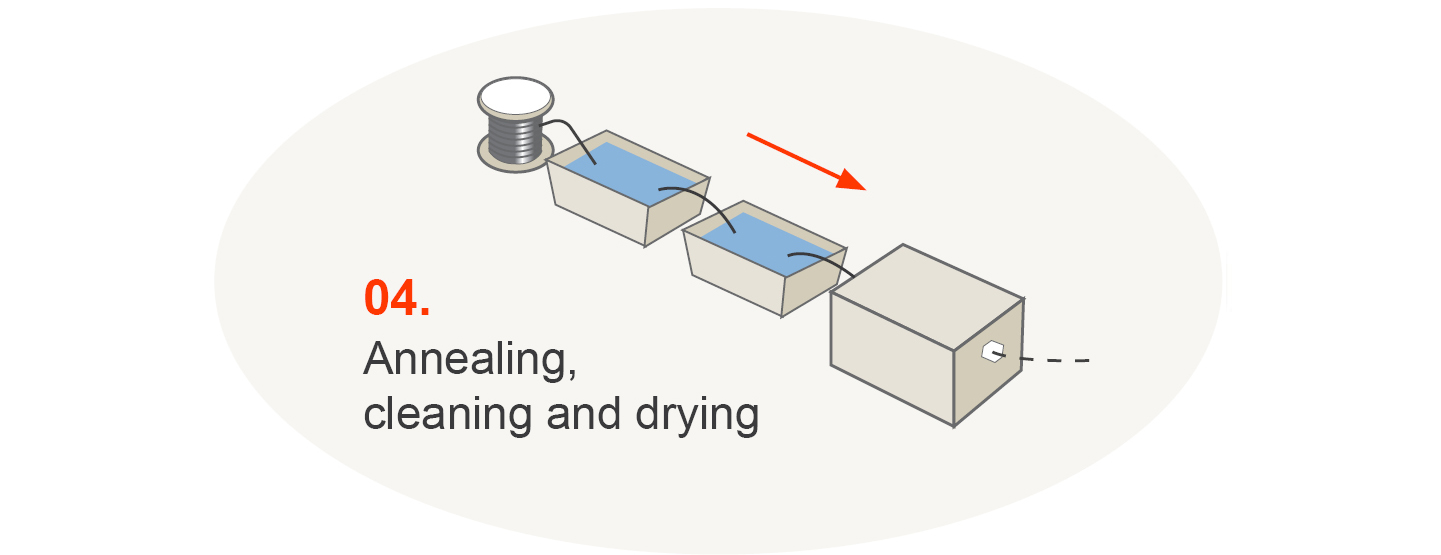

What is annealing?

- Annealing process for fine tuning of mechanical characteristics for easy handling and faultless wire.

- This also allows reducing the frequency of tensioning in vineyard. There are many wires with the same diameter, tensile strength and elongation. Some of them will break after five times bending when Crapal® lasts years and years. The right choice of high quality wire rod and our expertise in processes explain the difference.

At this stage the wire has the required mechanical properties and is ready to receive the protection for the use in vineyard.

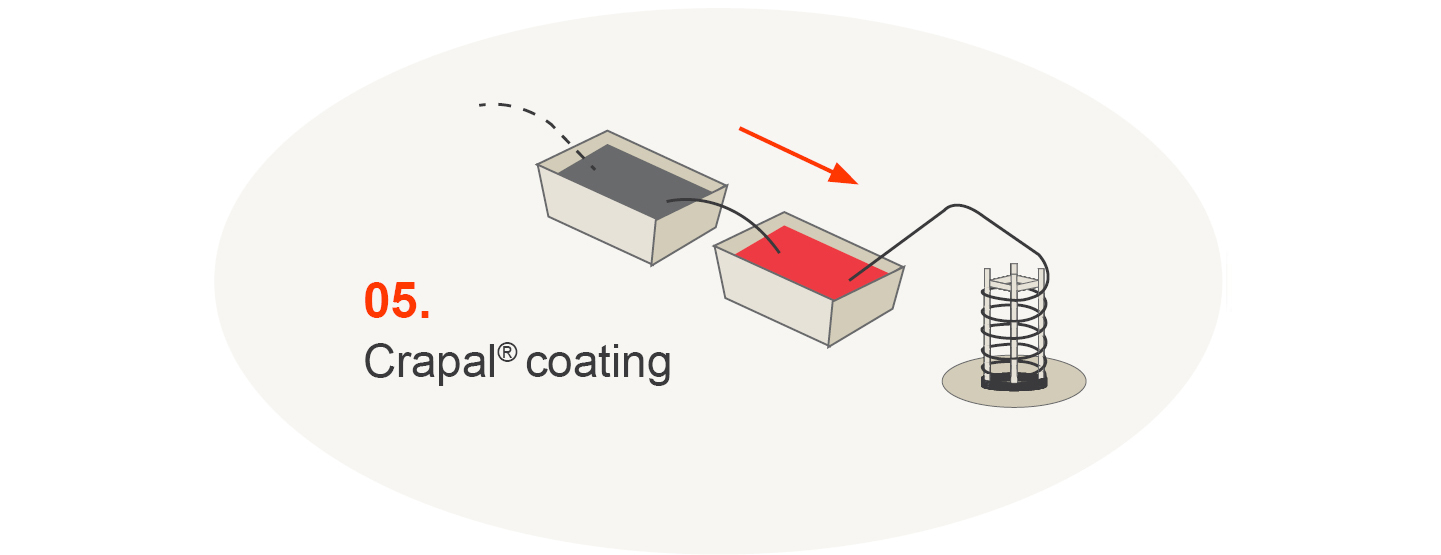

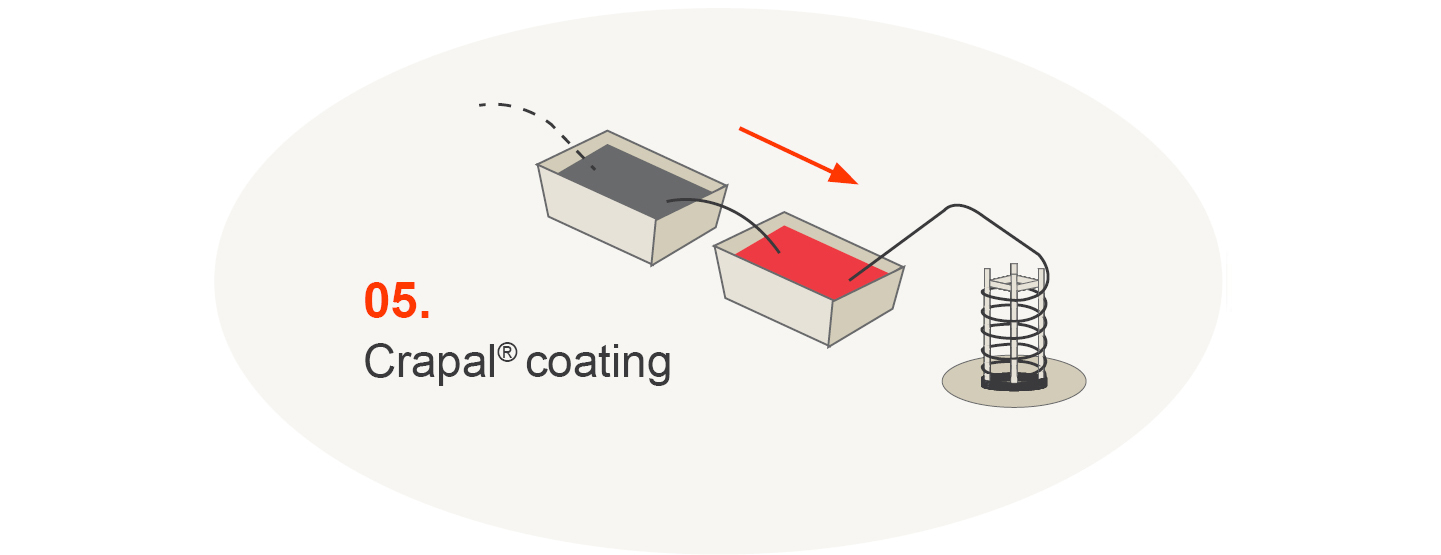

What is galvanisation?

- Application of a protective layer to the wire to prevent or inhibit corrosion.

Packaging

- Crapal® is available in 25 kg spooled coils automatically produced by a robot; this means easy twist-free unwinding.

- Coils are bound with orange plastic straps improving safety at work.

- Each coil is labelled with useful tips written on the back side.

- Remember: in each 25 kg coils of Crapal® you receive more meters compared to traditional wires.