ArcelorMittal Duisburg plant is located in the Ruhr region in north-west Germany. ArcelorMittal Duisburg works to develop new applications and new products for the automotive, energy and mechanical industries.

The billet mill produces high quality billets and SBQ for the forging industry. The new wire rod mill supplies the automotive market with cold heading, spring grades, bearing and other special wire rod grades.

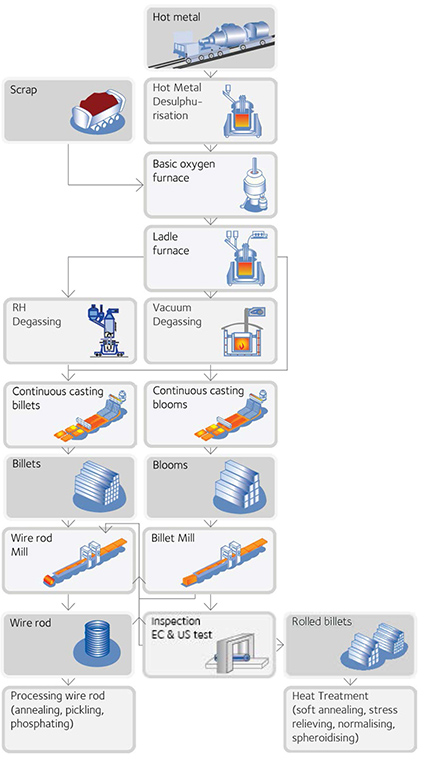

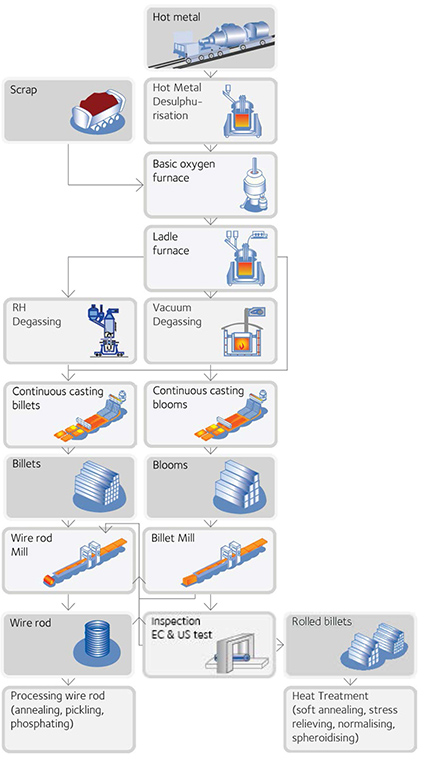

Facilities

- Steel plant:

Two oxygen converters (TBM process)

Ladle furnace

Steel ladle vacuum treatment: circulation degasser (RH) and tank degasser (VD), as per metallurgical need

Steel conditioning (Argon & Nitrogen stirring)

1 Bloom caster with soft reduction

1 Billet caster

- Billet rolling mill:

Reversing breakdown and finishing stand

- Inspection line for bars & billets:

Conditioning with ultrasonic and surface testing (TOM) annealing devices (up to 9 m in length): soft annealing, normalising

Dimension control

Surface grinding (including robot)

- Wire rod rolling mill:

High speed single-strand, 28 stands including pre-block

Thermo-mechanical rolling incl. loop

104 m long Stelmor line

- Wire rod processing (annealing, pickling, phosphating) upon request

Casted semis

- Blooms (mm): █ 265 x 385 - length (m): 4,3 -12,3

- Billets (mm2): ■ 320 - length (m): 4.3 -12.3

- Billets (mm2): ■ 160 - length (m): 12 -16

Finished products

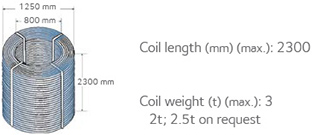

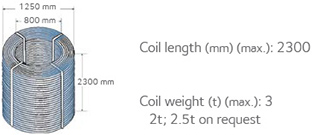

- Wire rod (mm): 5.5 to 25 (steps of 0.5 mm)

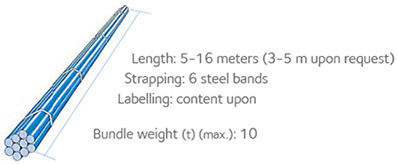

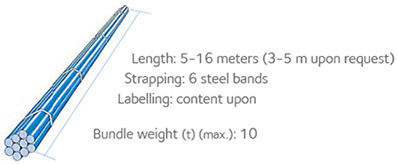

- Bars (mm): 100 to 170

- Bars (mm2): ■ 63 to 200 (round corner square)

Markets